-40%

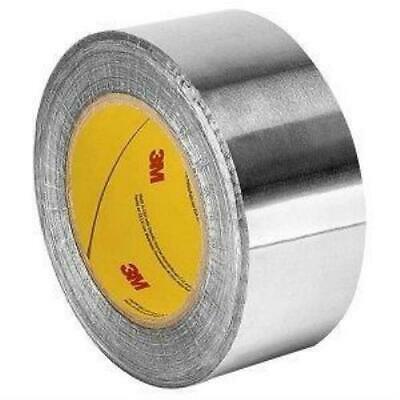

3M 1170 Conductive Tape - Roll Size 2" x 18 yd (By Roll)

$ 69.98

- Description

- Size Guide

Description

3M 1170 EMI Aluminum Foil Shielding Tape has a 2.0 mil smooth aluminum foil backing with a conductive acrylic pressure-sensitive adhesive and liner. Aluminum is an alternative conductive backing material to copper.3M 1170 Tape consists of a 1-ounce dead soft aluminum foil backing and a unique

electronically conductive pressure-sensitive acrylic adhesive.

• Dead soft 1-ounce aluminum foil backing

• Conductive acrylic adhesive

• Supplied on a removable liner for easy handling and die cutting

Like all 3M shielding tapes, 3M 1170 is available in standard and custom widths and

lengths. Standard length is 18 yards.

• Widths from ¼” to 23”

• Longer lengths up to several times normal length, dependent upon width. Check with Customer Service.

3M 1170 Tape is typically used for applications requiring excellent electrical conductivity from the application

substrate through the adhesive to the foil backing. Common uses included grounding and EMI shielding in

equipment, components, shielded rooms, etc.

Many factors determine the true shielding effectiveness of a shielding tape, including type and thickness of foil,

adhesive type, intimacy of contact, smoothness of application surface, strength and frequency of the EMI

signal, etc. However, using standard tests and fixtures, it is possible to determine a value for the attenuation.

For 3M 1170 Tape, typical shielding effectiveness (far field) is in the range of 60dB to 75dB (30 MHz to 1 GHz).

Properties Typical Values:

Backing thickness 2.0 mil (.05mm)

Total thickness (backing plus adhesive) 3.2 mil (.081mm)

Breaking strength* 20 lb./in (35 N/10mm)

Adhesion to steel* 35 oz/in (3,8 N/10mm)

Electrical resistance through adhesive** 0.010 ohm

Flame retardancy*** Pass

Footnote:

*Test method ASTM D 1000

**MIL-STD-202 Method 307 maintained at 5 psi (3,4 N/cm3) measured over 1 in surface area. Conductive particles in the adhesive

provide the electrical path between the application substrate and the foil backing.

***UL-recognized for flame retardancy per UL 510, Product Category OAMZ2, File E1738